Our process engineers are experts in biological treatment technologies for wastewater treatment across a wide range of situations. Our services include design, build and operations and often involves integrating other technologies to deliver a complete end-to-end solution for our clients.

We specialise in creating biological, sustainable wastewater treatment solutions that help councils, utilities, and private companies improve water security, reduce costs, and capitalise on water reuse opportunities.

Read our Wastewater and Leachate Capability Statement for full details of our expertise and knowledge.

Our biological treatment solutions are utilised to treat many clients' wastewater, targeting common contaminants such as ammonia, nitrogen & BOD.

Technologies we deploy

SBR (Sequencing Batch Reactor)

Our SBR systems deliver efficient, robust wastewater treatment for leachate, municipal and industrial applications. Our highly configurable SBR technology ensures compliance with discharge quality requirements under fluctuating loads in a minimal footprint with low energy consumption.

MBBR (Moving Bed Bio Reactor)

MBBR systems provide an efficient, compact wastewater treatment solution. We have unique expertise in anoxic MBBR technology which ensures stable nitrogen removal performance under varying loads with reduced operational complexity.

Trickling Filters (fixed and random pack media)

Modern Trickling Filters utilising fixed and random pack media are a high rate, low energy solution for nitrification of ammonia and BOD removal. Our partners Brentwood are a global supplier of trickling filter media. Through our subsidiary Trickling Filters Australia, we have exclusive rights to the distribution of Brentwood trickling filter media in Australia.

Anerobic Digestion

We offer a range of Anerobic Digestion solutions for both high strength wastewater and organic solids into renewable energy whilst reducing sludge volumes and treatment costs. With our strong focus on sustainability, our technologies deliver efficient biogas production and nutrient recovery for a greener, cost-effective operation.

Where we service

Landfill Leachate

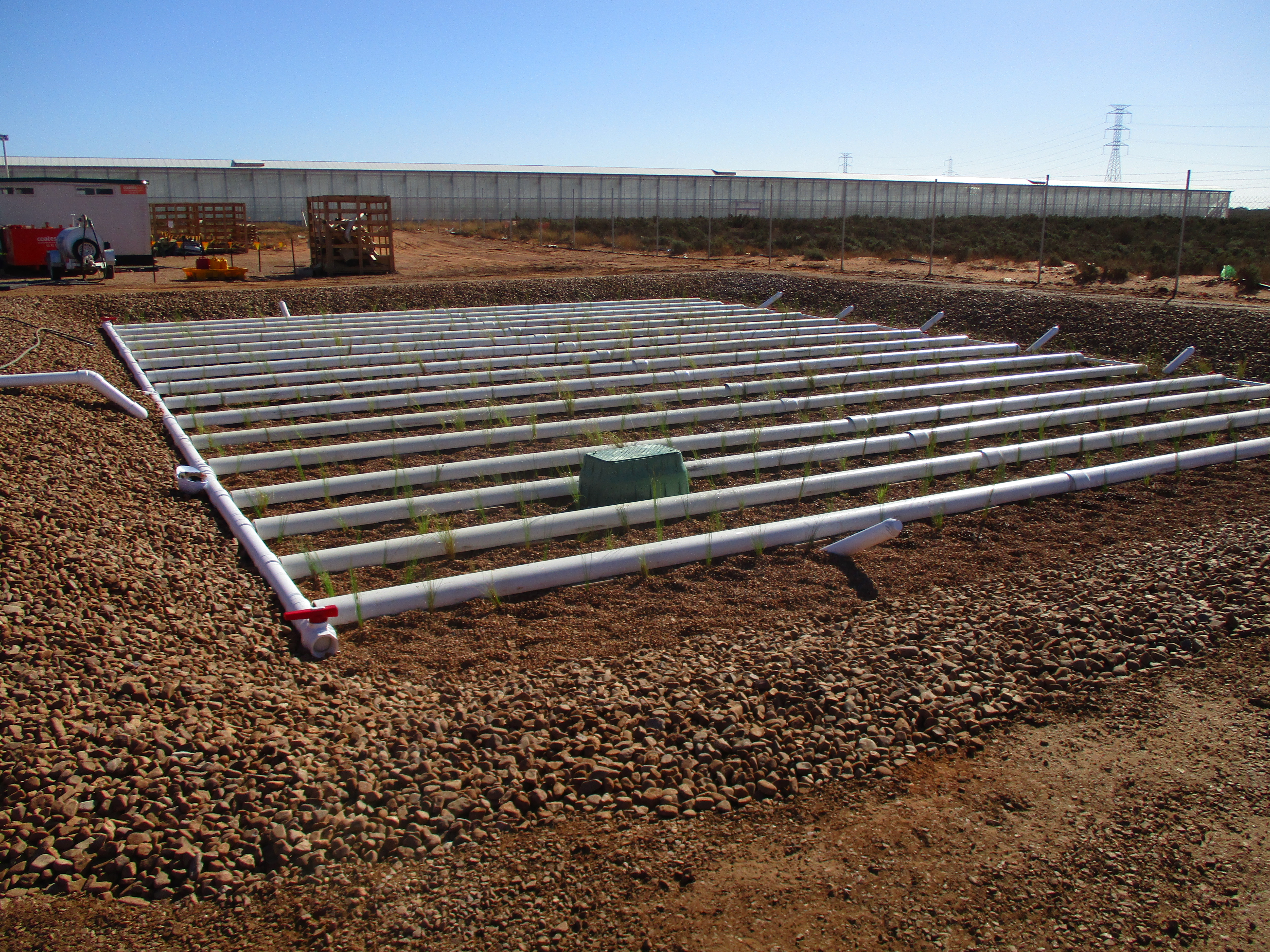

Landfill leachate differ in composition, along with seasonal flows and concentrations. Due to this variability, we develop bespoke treatment systems for our clients. They incorporate multiple process steps and are designed specifically around the characteristics of the leachate and the final water quality that is required.

Our team can engineer solutions using a wide range of conventional and ecologically based technologies. Our breadth of knowledge provides an increased number of options to optimally match the treatment train to the wastewater composition.

We also have the skillset to integrate treatment with sustainable disposal and reuse solutions, such as irrigated forests and vetiver grass plantations.

Additionally, our team has developed a proprietary PFAS treatment system (LEEF System®), especially for use in leachate and wastewater.

Municipal Sewage

Our aim is to develop bespoke, future-proof solutions that accurately meet our client's requirements and generate positive environmental and community-based co-benefits.

Through incorporating strong process optimisation initiatives, refurbishments and surrounding landscape integration, we are regularly able to achieve sizable capital savings, lower operational cost and reduced energy consumption within our treatment systems.

Industrial Wastewater

The varying compositions of industrial wastewater require the development of bespoke treatment solutions to achieve optimal outcomes.

We approach each project by determining the options for final disposal, quantifying performance requirements and thoroughly understanding client drivers. When viable, we always aim to leverage our expertise in ecologically based treatment systems to achieve a lower energy, more sustainable treatment solution.

Mining water

We approach mining wastewater treatment projects uniquely, by aiming to integrate our wastewater solutions into the long-term remediation plans of a site. Instead of addressing the issues separately, our team can engineer solutions that take advantage of reuse opportunities and create whole-of-life solutions that generate stronger co-benefits.

Our final process solutions are developed on a case-by-case basis, ensuring the characteristics of the wastewater and site are taken into account, along with other treatment goals and sustainability targets.

Trickling Filters

Innovations in plastic media has allowed trickling filters to drastically increase their level of effectiveness for a given treatment volume. Boasting 95% reductions in BOD and ammonia, plastic media trickling filters are a highly viable secondary treatment solution.

A key advantage of trickling filters, compared to other treatment technologies, is their very low power requirements.

Media can be supplied as complete modules or flat packed for on-site assembly. Our welding technology is environmentally friendly and does not use any solvents containing adhesives.

PRODUCTS

ENEXIO 2H BIODEK ® CROSSFLUTED MEDIA — HIGH EFFICIENCY — LOW EFFLUENT RATES

BIOdek® cross-fluted media (surfaces from 70 — 320 m2/ m3) provide reliable performance for biological sewage treatment processes. The different shapes of media allow for growing thin or thick biofilms depending on the process that is required.

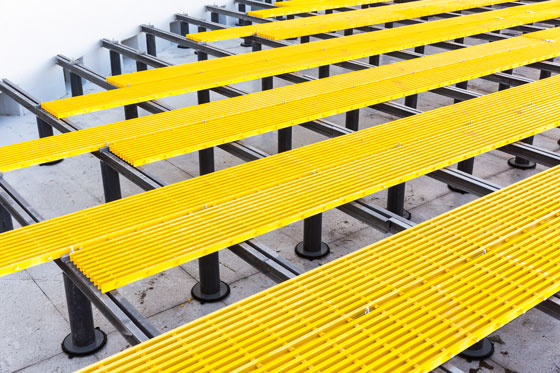

PIERDEK® SUPPORT SYSTEM

The PIERdek support system is robust, durable and simple to install for all types of structured media trickling filters. The upright supports are adjustable to accommodate for all concrete base designs, ensuring an even platform for the media.

ENEXIO 2H BIODEK ® VERTICAL FLOW MEDIA — OPTIMUM SOLIDS DISCHARGE

Trickling filters and submerged fixed beds must have a balance between the new growth of biomass and the surplus sludge discharge. BIOdek® vertical flow media's tube channels enable the sludge discharge by water or air flushing. Their processes are best suited for higher organic loads with high growth of biomass.

Random Packing Media

Random packing media provides an inexpensive way to upgrade your current system as it can use your existing infrastructure commonly without the need for additional capital works.

Media is supplied premade in various configurations with differing sizes and surface area measurements.

PRODUCTS

2H RANDOM MEDIA

2H Random Media provide a large protected surface for the growth of biofilm. It's specifically designed to be installed in trickling filters and submerged moving bed reactors for both sewage and industrial wastewater treatment.

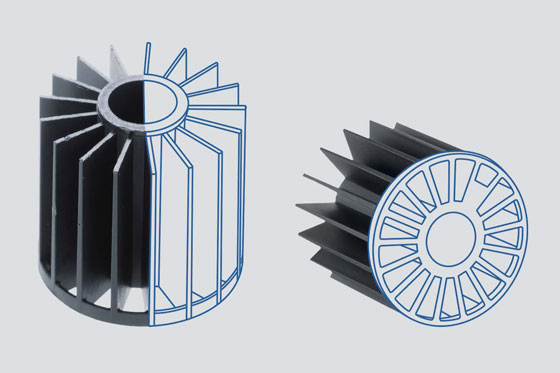

Rotating Distributors (Distribution Arms)

Rotating Distributors are responsible for the equal and specified distribution of effluent over tricking filters. Modern distributors are specifically designed to reduce energy usage and maintenance cost, boasting expected lifespans of over 20 years.

VA Teknik Rotating Distributors can be installed in both new and existing wastewater treatment tanks and can be tailored to meet specific project requirements.

Maximising the usable surface area of the trickling filter through upgrading the rotating distributor can translate into considerable cost savings and better treatment outcomes.