Celebrating one year of successful PFAS and leachate treatment at Shoal Bay

1 November, 2023

One year ago, the Water & Carbon Group (WCG) in collaboration with the City of Darwin, marked a significant milestone with the commissioning of the Shoal Bay Leachate Treatment Plant. This introduced a world-first advancement in treating per- and poly-fluoroalkyl substances (PFAS) in leachate —the Low Energy Evaporative Fractionation (LEEF) System® —and the results have been nothing short of exceptional.

PFAS are a synthetic group of chemicals, commonly known as ‘forever chemicals’, that have been manufactured for use in a wide range of consumer and commercial products. As these products reach the end of their useful life, they are discarded, finding their way into landfills.

Setting a new standard in PFAS removal

The Shoal Bay Waste Management Facility receives more than 180,000 tonnes of waste each year from 164,000 residents who live in the greater Darwin region. Due to the region’s high rainfall, the facility also generates large volumes of leachate that must be treated and kept out of the surrounding environment, which includes ecologically important habitat.

The LEEF System® removes PFAS at the Shoal Bay Leachate Treatment Plant in Darwin.

With the leachate issue in mind, Darwin’s pioneering leachate treatment facility was constructed at Shoal Bay, combined with the patented LEEF System® technology, redefining the removal of PFAS. The process is one-of-a-kind and a remarkable success in reducing targeted PFAS compounds to very low levels in landfill leachate. Since its commissioning, the plant has exceeded expectations and is setting a new standard for efficient and feasible solutions to PFAS contamination.

Nick Fewster, Executive Manager of Environment and Waste Services at City of Darwin, emphasized the importance of addressing leachate and PFAS concerns in waste management facilities.

“Leachate, and PFAS within leachate, is an issue for all waste management facilities. Our commitment at the City of Darwin was to tackle these contaminants using an innovative approach to protect the local environment and the community. Investment in this innovative leachate & LEEF System PFAS treatment technology has enabled City of Darwin to treat large volumes of leachate generated in a high rainfall environment. We’re proud to say that this achievement positions Darwin as a global leader in leachate and PFAS treatment."

- Nick Fewster, Executive Manager of Environment and Waste Services at City of Darwin

Engineering a new solution to PFAS

After being awarded a $13 million contract by the City of Darwin, WCG designed and engineered a PFAS treatment solution after finding that there was nothing ‘off-the-shelf’ that was feasible. The result was the LEEF System®. This patented process has been installed as a key component of the leachate treatment plant, specifically to remove PFAS from the leachate.

The LEEF System® uses foam-fractionation to remove more than 99 per cent of PFAS contaminants. Foam fractionation takes advantage of the way PFAS attach to air bubbles and then by introducing controlled amounts of air into the system in a specific manner, the air bubbles rise to the top and then are skimmed off, and the PFAS contaminants are removed.

The LEEF System® uses foam fractionation and a patented process to remove PFAS.

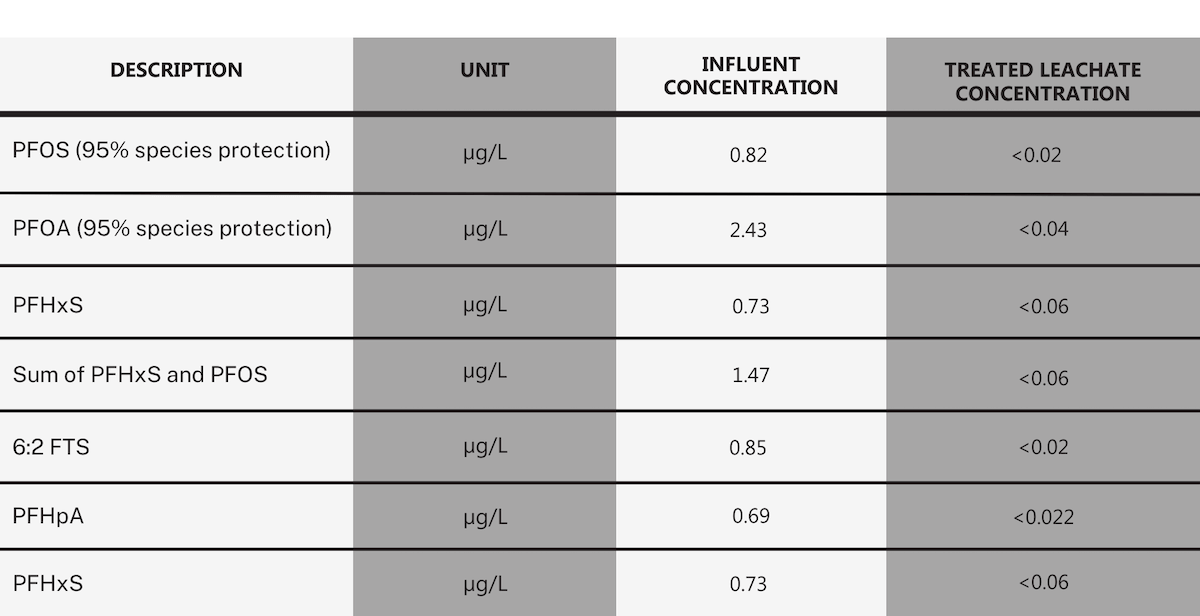

Exceptional PFAS removal results

David Leinster, WCG’s Wastewater & Solutions Development Manager, said in full production the plant was processing up to 140,000 litres of leachate daily, but its capacity can be readily scaled to meet higher demands or scaled down as needed.

“What sets this plant apart is its ability to produce a very small, PFAS enriched waste stream without the use of chemical additives. It operates with low energy consumption and operational requirements and eliminates the need for costly pre-treatment. This contrasts with your more conventional methods like reverse osmosis, which tend to be more costly.

The system is a continuous flow system, and is designed to be both scalable and modular, allowing for easy customisation to suit specific site requirements. In addition to removing PFAS, the plant integrates biological and ecological treatment processes in a closed loop system. We’re seeing some phenomenal results with regulatory requirements not only being met but exceeded.”

- David Leinster, WCG’s Wastewater & Solutions Development Manager

PFAS removal results from the LEEF System® at the Shoal Bay Leachate Treatment Plant in Darwin.

A continuous improvement mindset

During the annual shutdown of the leachate treatment plant, modification work was carried out to further enhance the performance of the LEEF System®. Linc Symons, WCG Site Operations Manager at Shoal Bay, said he was excited about the results achieved in quality from day one at Shoal Bay and was proud of the team’s involvement in transition from construction through commissioning and into operation of the plant.

“New project rollouts always have their challenges, but this project has been very good in comparison to others I've been involved in,” he said.

“We had some issues with telemetry and access to communication services, but these were worked through quickly. Removal of organic waste also provided challenges along the way but WCG have a very diverse and unique employee base so there is always an answer and resolution.”

Linc said he saw Shoal Bay as the flagship site for WCG. Having a research and development focus was also underpinning the robustness of the system and making a difference to other projects.

“The knowledge we have gained in the past year will help other projects, like those underway to roll out LEEF in the US,” he said.

Linc Symons, WCG Site Operations Manager at Shoal Bay, talks about the PFAS-removing LEEF System® and the unique leachate treatment plant.

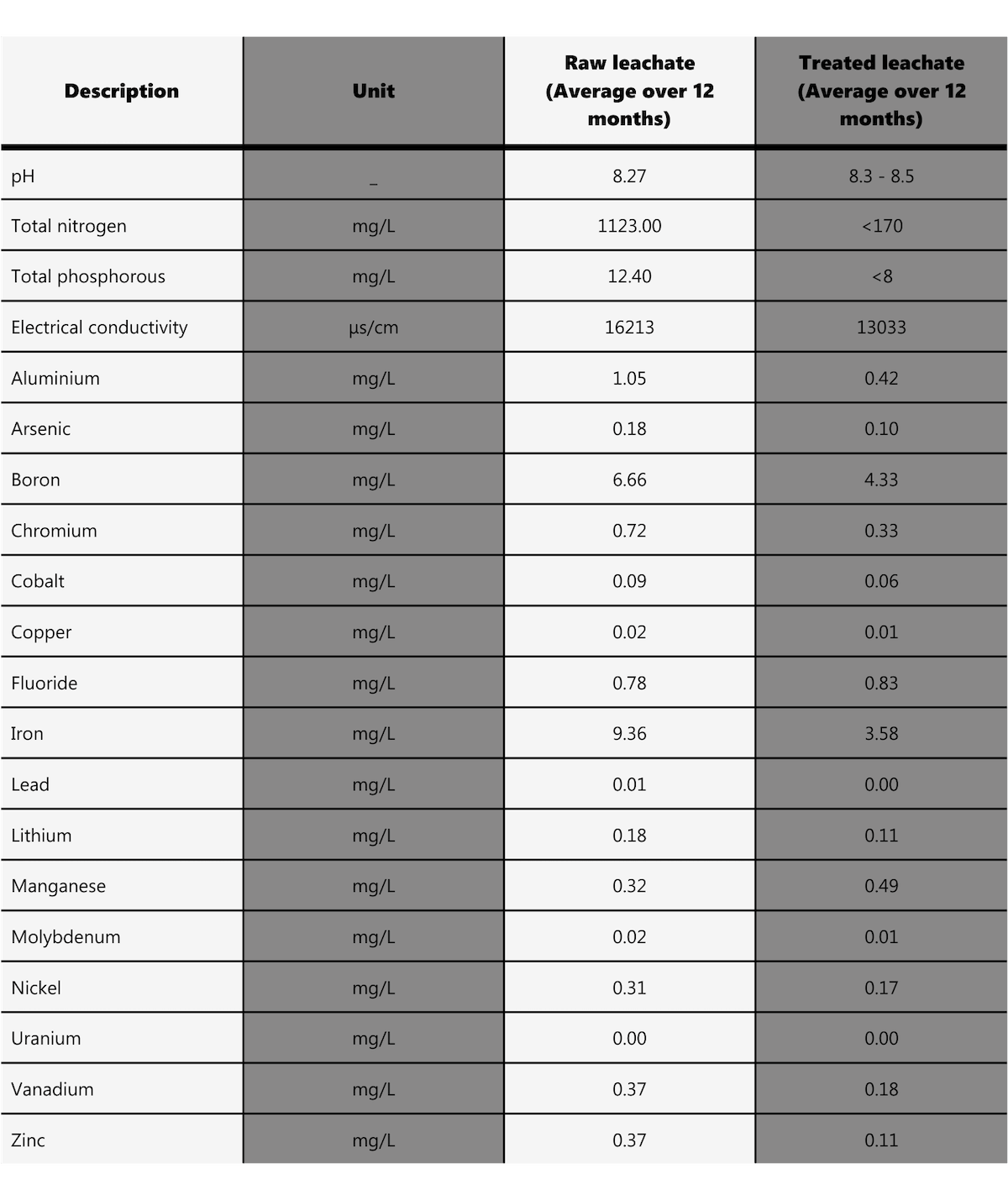

Treating more than PFAS

The plant is also treating a host of other toxins found in leachate. Treated effluent from the LEEF System® is further processed via a biological treatment plant which uses microbes for nutrient removal and a treatment wetland for a final polishing, further reducing residual nutrients and heavy metals.

Finally, the treated leachate is used to irrigate a vetiver grass crop. This is a process of phytoremediation, whereby plants are used to clean up the remaining contaminates. Evapotranspiration results in a zero liquid discharge closed loop treatment solution.

Results from the Shoal Bay Leachate Treatment Plant show removal of a host of contaminants in leachate.

Going global

Jim Hunter, CEO of the Water & Carbon Group, said the leachate treatment plant and the LEEF System® had achieved, if not exceeded, all project targets and had reduced operational costs to below budget.

“It’s an extremely efficient and effective solution in addressing the City of Darwin’s leachate challenges,” Mr Hunter said.

“It’s a great result and I couldn’t be prouder of our team who designed, constructed and continue to operate the system on a daily basis to ensure it delivers the best results.”

The future for LEEF is now going global with WCG set to commission its first operational LEEF System® in the US in early 2024, with client Waste Connections at their Bethlehem Landfill in Pennsylvania.

Find out more about our PFAS treatment solution, the LEEF System®. Contact us today to talk to our PFAS and wastewater experts.